Good Machinability and Mirror Lapping Performance Aluminum Alloy Steel Die Casting Mold ...

Ningbo Xinhao Machinery Co., Ltd.- Using Hardness:HRC28-34

- Surface Treatment:Heat Treatment

- Demoulding:Automatic

- Material:Aluminium

- Application:Electronic, Commodity

- Mould Life:500,000-1,000,000 shots

Base Info

- Transport Package:Wooden Packaging or Pallet

- Lead Time:15-30 Work Days Depends on The Structure and Size

- Design Software:Ug or CAD

- Treatment:Pre-Harden Heat Treatment Quenching

- Condition:New

- Customized:Customized

- Certification:CE

- Trademark:XinHAO

- Origin:Ningbo

- HS Code:8480200000

- Production Capacity:6000t,Year

Description

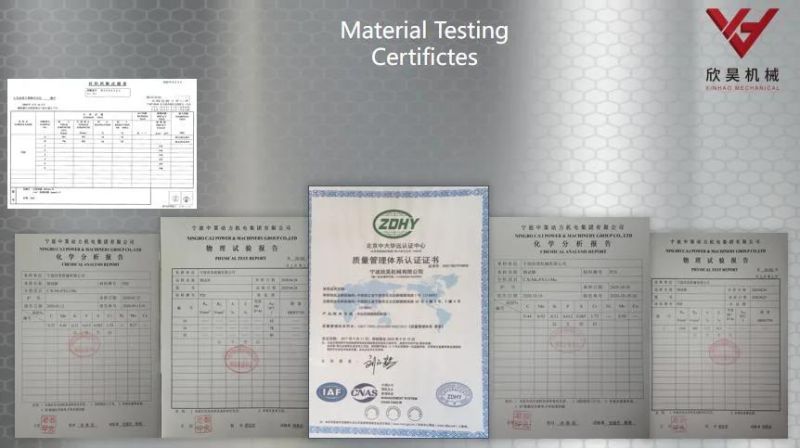

Quality Control Process:

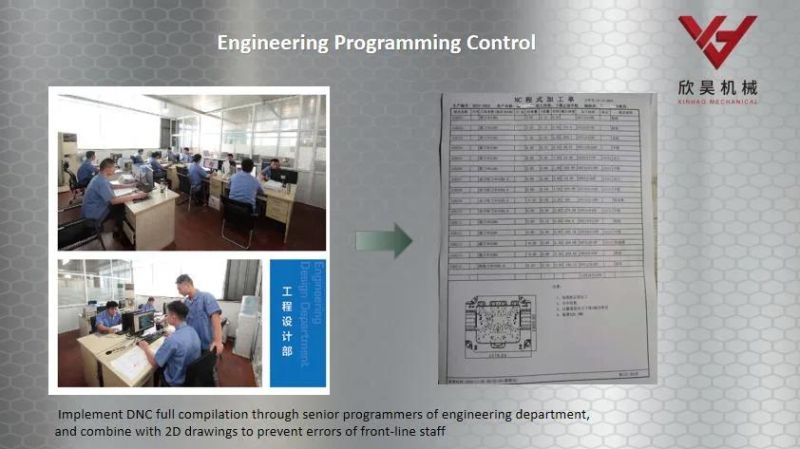

Engineering Programming Control:

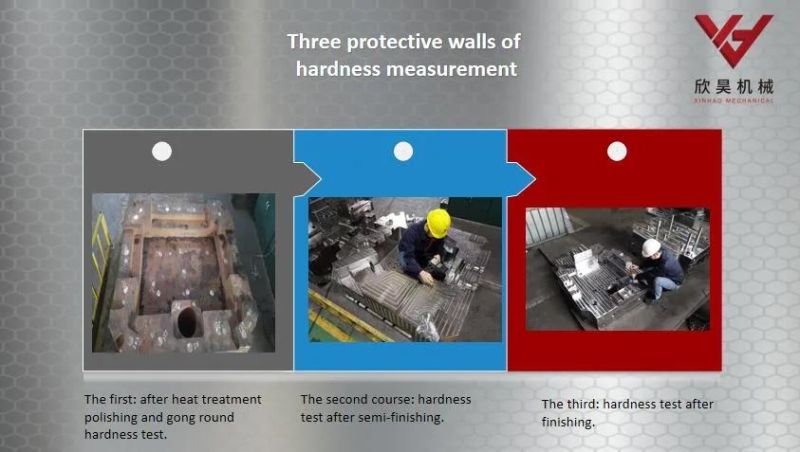

Hardness Measurement:

Process Guarantee:

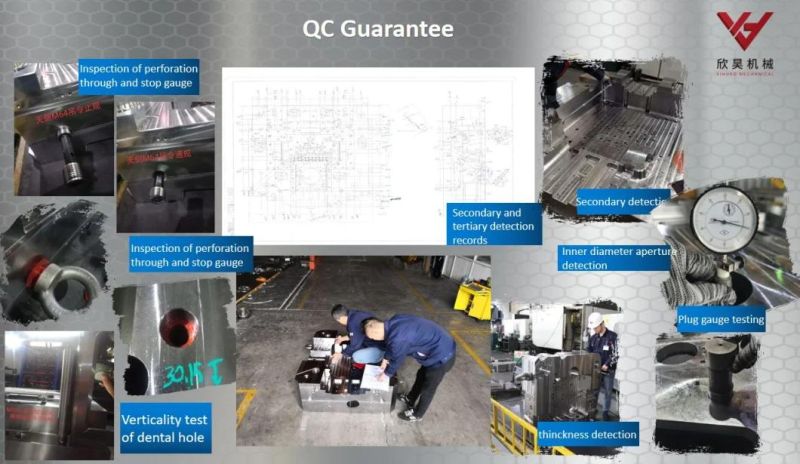

QC Guarantee:

Products Show:

Market:

FAQ:

1. Q: Are you manufacturer or Trading company?

A: We are manufacturer with more than ten years experience in this field. Cover over 5,000 square meters manufacturing department. Products cover large,small,medium die-casting moulds including new energy auto parts and communication die-casting products etc.

2.Q: What is the delivery time?

A: For Customized products such as the die casting mold, we try our best to track the product progress and inform oversea client the details every week.

3.Q: Could you list you main customers?

A: JiLi Cars, Tuo Pu,Haiwei,Changcheng joint large mold factory such as ,Guangzhou Cavity Mould Manufacturing Co. Ltd , etc., and some new energy vehicle brands such as Zhijun, Lingpao, Hezhong, etc. It has been affirmed by our customers and has become a rising star in the field of automobile body molds.

4.Q: What does your company need to submit a quotation?

A:2D or 3D drawing of the die-casting mold base, together with relevant information, such as quantity,weight material. Most of our products are customized , so we need as detailed as possible information to design for you.

5.What kind of format of the drawing?

A: PDF, 3D Drawing of the metal die-casting parts.