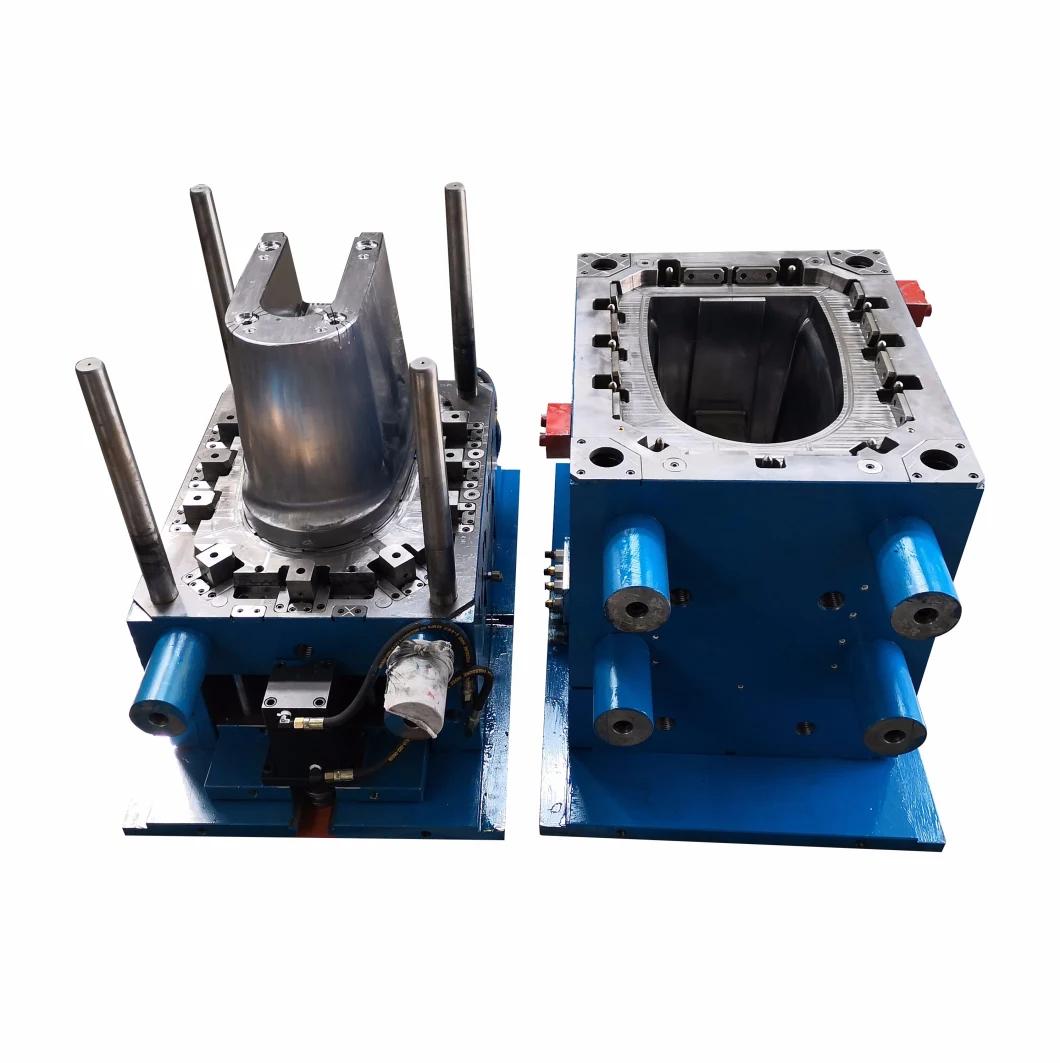

Customized/Designing Auto Parts Light Cover Plastic Injection Mould

Ningbo Moldie Mold Co., Ltd.- Plastic Material:Customized

- Mould Cavity:Single,Multi

- Surface Finish Process:Customized

- Shaping Mode:Injection Mould

- Warranty:1 Year

- Process Combination Type:Single-Process Mode

Base Info

- Service Life:0.5-5 Million Cycle Times.

- Dimension Tolerance:0.01mm

- Payment Term:T,T, Western Union, Paypal etc

- Lead Time:About 3-6 Weeks Regarding to Your Design

- Appication:Automotive

- Color:Black, White or Reference to Panton

- Shape:Regarding to Client Drawing or Sample

- Mould Standard:Hasco, Dme and Misumi Ava

- Software:Solidworks, PRO-E, Ug, Autocad

- Part Material:ABS, PVC, PC, PA6, POM and So on

- Mold Material:P20, 1.2344, 1.2738, Nak80 and So on

- After-sales Service:Accept

- Customized:Customized

- Standard:Hasco, Dme, Misumi, Punch

- Certification:ISO

- Installation:Mobile

- Design Software:Ug, PRO-E, Solidworks, Autocad

- Runner:Customized

- Application:Car

- Model NO.:Customized

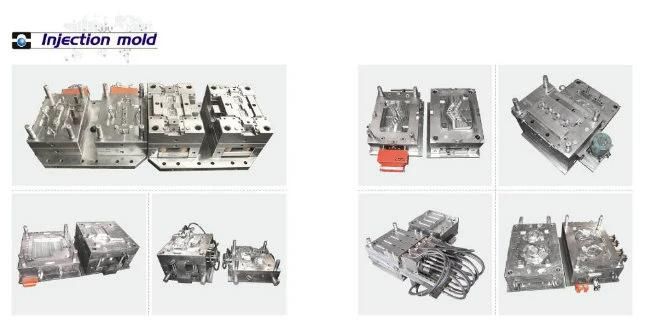

- Mold Type:Plastic Injection Mold

- Transport Package:Wooden Box

- Specification:ISO 9001: 2008 and SGS Certificate

- Trademark:Customized

- Origin:Ningbo, China

- HS Code:8480719090

- Production Capacity:60 Sets,Month

Description

Basic Info.

Model NO. Customized Application Car Runner Customized Design Software Ug, PRO-E, Solidworks, Autocad Installation Mobile Certification ISO Standard Hasco, Dme, Misumi, Punch Customized Customized After-sales Service Accept Mold Material P20, 1.2344, 1.2738, Nak80 and So on Part Material ABS, PVC, PC, PA6, POM and So on Software Solidworks, PRO-E, Ug, Autocad Mould Standard Hasco, Dme and Misumi Ava Shape Regarding to Client Drawing or Sample Color Black, White or Reference to Panton Appication Automotive Lead Time About 3-6 Weeks Regarding to Your Design Payment Term T/T, Western Union, Paypal etc Dimension Tolerance 0.01mm Service Life 0.5-5 Million Cycle Times. Mold Type Plastic Injection Mold Transport Package Wooden Box Specification ISO 9001: 2008 and SGS Certificate Trademark Customized Origin Ningbo, China HS Code 8480719090 Production Capacity 60 Sets/MonthProduct Description

1. Custom molds2. Reasonable price

3. Good at Automotive mold

4. ISO 9001: 2008 Certificated

5. With Europe market since 2004

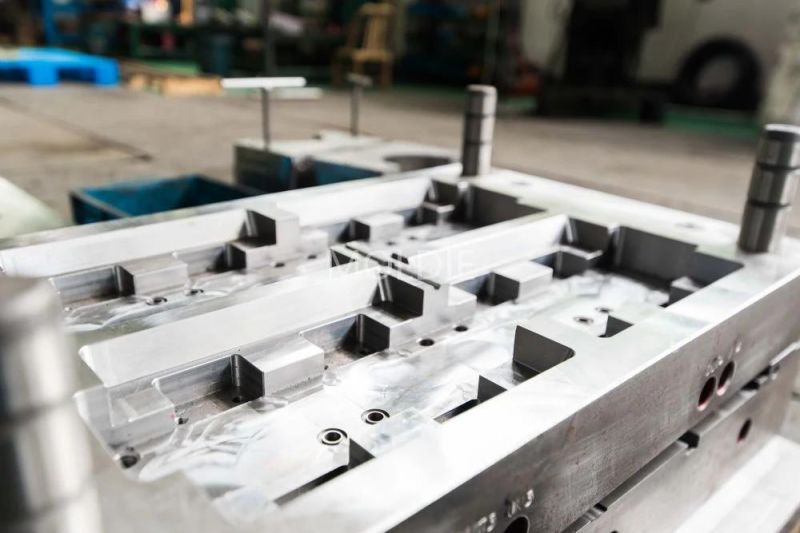

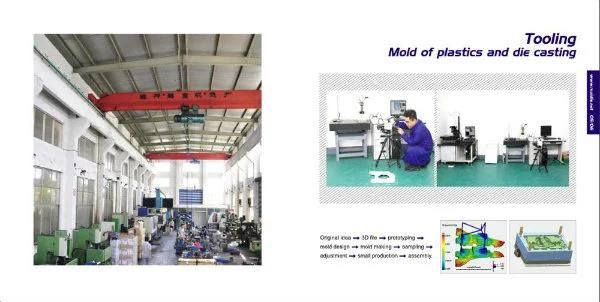

MOLDIE specializes in manufacturing and supplying of prototypes and various moulds and dies, such as plastic injection moulds, die casting molds and progressive dies since 2004.

MOLDIE provides various molds & dies to the clients from Germany, USA, Spain, Italy, Russia and so on.

"Good quality" is the base of MOLDIE business, as all MOLDIE staff know quality is essential condition for mechanical products, MOLDIE must keep our clients in a safe condition.

ISO 9001: 2008 certificated.

Advantages:

1. Competitive price

2. Strict quality control system

3. Quick mold making and delivery

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Special info.:

| Item | Description |

| 1. Mould material | P20, 718H, 45#, STAVAX ESR S136, H13, 2316, 2083, 2344 |

| 2. Hardness of steel | Vacuum quenching, nitride, HRC41-47, HRC46-50, HRC60 |

| 3. Inserts / Slider steel | H13 (DIN. 1.2344), tempered with HRC46-50 |

| 4. Mould spare parts | H13 (DIN 1.2344), tempered with HRC40-45, nitrited with HRC60-62 |

| 5. Mould base | LKM, HASCO |

| 6. Mould cavity | Single / Multi |

| 7. Runner system | Hot / Cold |

| 8. CAD centre for data formats | IGES, X_T, STP & DWG, etc |

| 9. Plastic material | ABS, PC, PE, PP, PS. |

| 10. Mould life | 500000- more than 5000000 |

| 11. Delivery time | 4-8 weeks |

| 12. Terms of payment | T/T, Paypal, Western Union andso on |

Our Services

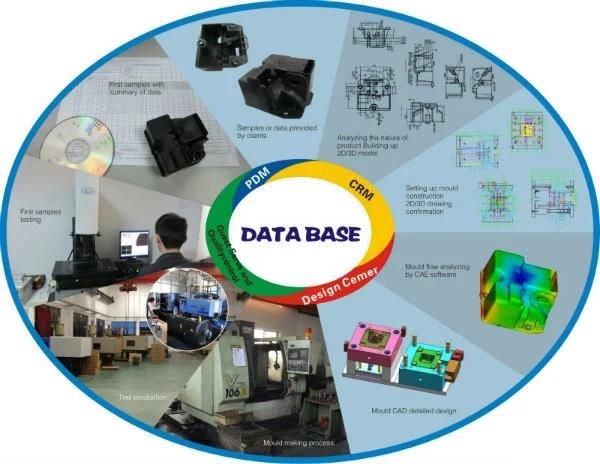

1. Product Design, Structural Optimization, Process Optimization

2. Mold Making, Plastic Molding Parts, Casting Parts, Machining Part

3. Manage Project, Control The Delivery and Quality of Products

4. Arranging the Transportation, Customs Clearance and other Matters for You

MOLDIE (molds & dies) specializes in manufacturing and supplying of prototypes and various molds & dies, mainly for three different types, plastic injection molds, die casting molds and stamping progressive dies.

All molds design are carried out in accordance with clients' requirements and specifications. And professional

Engineers team take care all details for whole process during project running.

Since 2008, MOLDIE has been working with many customers from Germany, Spain, Italy, USA, Russia and so on. For automotive field, our indirect customer includes Mercedes Benz, Volkswagen, GM, Chyrsler, Maserati and so on. For other filed, we make molds & dies for IEK and so on.

We apply ISO9001: 2008 into our quality management system to ensure all molds & dies that are exported by

MOLDIE are high quality standard.

Our enthusiastic and highly motivated staff are looking forward to receiving your emails.

Long term business whilst assuring you of the best services at all times.

We have one professional engineers team to design the mold and check the design to make sure all are right before production. My engineers follow the molds' production every week to make sure all of them are in schedule; After trial production, we will check the samples about the finishing and dimension to make sure samples are right or not and make report to our clients; We do the final inspection on molds before mold shipment. We are one of professional company to provide you good quality molds with good price in time.

Packaging Details: Carton and pallet, rust-proof protection.

Delivery time: 10--20 working days after the deposit, 3--4 working days for the inventory

Packing: Neutral Carton, Wooden Case for the large items

Shipping: By Sea, By Air and By Express Delivery

FAQ1. Q: Can you make the production mold with short run production?

A: Yes, we can. We can make the production for any quantity you want.

2. Q: How do we control the mold processing?

A: We will send the processing report and mold processing picture every two week to the customer.

3. Q: Is the samples free of charge?

A: Yes, the first trial samples (5~10PCS) is free, and we will send you the samples by DHL, FedEx or TNT as soon as we finish the first samples.

4. Q: Who own the mold?

A: Customer