Gmt Reinforcement Beam Mold

Taizhou Huangyan Ningguang Mould Co., Ltd.- Demoulding:Automatic

- Cavity:Multi-cavity

- Material:P20

- Product Material:Iron

- Application:Solar Energy

- Heating System:Oil

Base Info

- Trademark:TOOLEX

- Specification:ISO9001: 2000

- Transport Package:Wooden Case

- Name:SMC Mould

- Customized:Customized

- Warranty:1 Year

- Certification:CE

- Mould Life:300000-1000000 shots

- Model NO.:TXS805

- Origin:Huangyan, China

- HS Code:8480719090

- Production Capacity:20 Sets, Month

Description

Basic Info.

Model NO. TXS805 Mould Life 300000-1000000 shots Certification CE Warranty 1 Year Customized Customized Name SMC Mould Transport Package Wooden Case Specification ISO9001: 2000 Trademark TOOLEX Origin Huangyan, China HS Code 8480719090 Production Capacity 20 Sets/ MonthProduct Description

Product Name | Gmt Reinforcement Beam Mold |

| Cavity and core steel | 1.2738 (28-32HRC) |

| Slider/lifter/cams | 1.2344 (H13) |

| Cavity/imprint | 1 |

| Ejection system | Ejector pins, ejector plates driven by hydralic cylinders |

| Heating system | Oil heating system /steam and electrical are optional |

| Mold finish | Technical polishing grain 400 + chrome plating |

| Vacuum system | Included |

| IMC system | Not included |

| Cycle time | 4 minutes |

| Mold life | 500000 shots |

| Mold type | Serial mold |

| Our Serive | MDF report / mold flow analysis |

| Weekly process report with photos | |

| Quality control team following project | |

| Trial report with video and free samples | |

| Sample and mould dimension report | |

| Optional service | bulk production |

| primer, top coating | |

| assembling & packing |

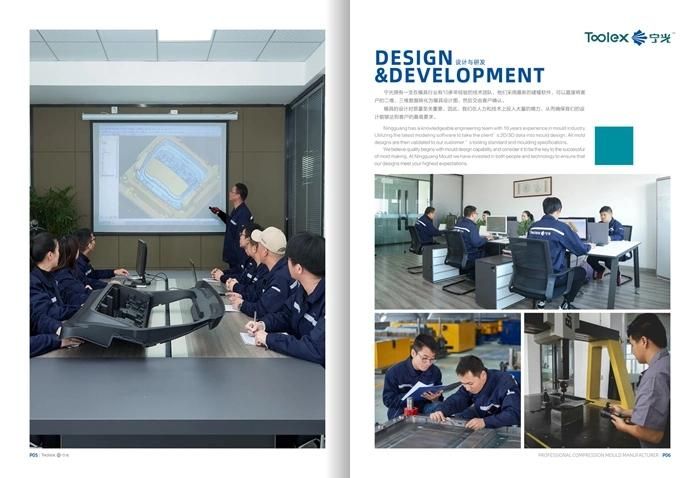

Based in Taizhou, Ningguang mold have been manufacturing tooling for

fifteen years. The company employees over seventy skilled people with

Very high retention rate.

The sales team all speak English and very experienced in matters relative

to the production of tooling or finished product with emphasis on understanding the client's needs.

A quality assurance program which is in place will give any potential client

Security knowing that they will receive a product that will be manufactured

According to their needs.

Our capacity in terms of die sizes are very large...up to 3.5 meters with a die

weight of around 50 tons. Mold size is never a problem to us.

Our experiences, our vision, our commitment to service reflect themselves

in our repeat customer base.