-

Dongguan Machinery Parts Mold Making WiFi Box Single Cavity Plastic Injection Mould ...

Why Choose Us?1)First-rate facilities: Mould Machine: 2 Mould Machines,4 EDM Machines,1High Speed CNC Carving and Milling Machine, 7 Milling Machines and 3 Grinding Machines Plastic Injection Machine:10 Plastic injection molding machine,6Precision injecti

-

Enclosure Wireless Router for Home and Office Use Electronic Products

General1. Making the sample until you are satisfied with it.2. Providing production schedule photos to ensure you know every process.3. Offering professional one-on-one service and replying to your E-mail within three hours.4. Shipment sample for checking before shipment.5. Priority to get our lates

-

Customize Hot Sell Mop Bucket Injection Mouldings Plastic Mould

The main Mold Steel and Hardness for you reference:Steel GradeS50CP20P20HH718H2738HH13S136NAK80Hardness(HRC)17-2227-3033-3733-3836-4045-5248~5234-402. Our Company3. Our Sample4. Our Exhibiton5. Production ProcessFAQQ: 1 Are you trading company or manufacturer ?A: We are factory.Q: 2 Where is your fa

-

EPP Foam Parts for Air Condition System

Product DescriptionFeatures ofETPU/EPP/EPS/EPO mould1) mould made of 5052 high-quality aluminum alloy2) With a standard frame and cooling system3) Covered with teflon to create non-stick surfaces, increase ejection ease and promote corrosion and heat resistance.Scope of mould:Our ETPU/EPP/EPS/EPO fo

-

Non-Standard Precision Processing Mechanical Customized Die Casting Mold Base for Tooling ...

OEM & ODM orders are welcome.Ningbo Xinhao Machinery Co,.LtdNingbo Xinhao Machinery Co.,Ltd is located in Dagang Industrial City of Beilun District, Ningbo, which is known as "thehometown of China's mould", with beautiful environment and convenient transportation. Established in Septem

-

Guaranteed Quality Plastic Bottle Preform Mold Moulding Frame Injection Plastic Mould

Basic Info. Model NO. pe-018

-

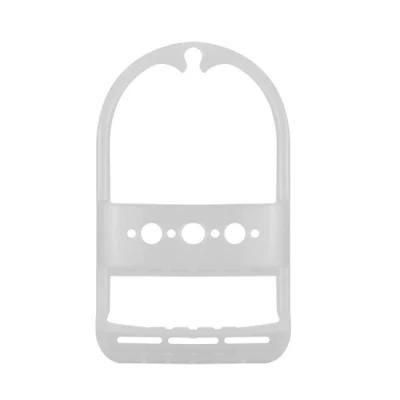

Injection Mold for Plastic Bathroom Shelf Rack Plastic Mold Plastic Mould

Basic Info. Model NO. GV-mold

-

Customized High Precision Plastic Injection Mold for Auto Parts

About usGlobalone Factory was founded in Shajing, Shenzhen in 1996, formerly Zechuan Mould.Globalone covers about6.800 square meters, has nearly 150 employees, and fully implements TS16949 and MMS production .Globalone is a professional manufacturer offering one-stop service from mold and part desig