Car Steering Wheel Plastic Injection Mold

Qingdao Root Industrial and Trading Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:PA66+GF

- Mould Cavity:2 Cavities

- Surface Finish Process:Polishing

- Shaping Mode:Injection Mould

- Application:Car, Electronic, Home Use

Base Info

- Specification:CE,RoSH

- Transport Package:Wooden Box

- Cold Runner:Available

- Injection Machine Size:50-1000 Tons

- Lead Time:25-35 Days

- Core Steel:2344

- Hot Runner:Yudo

- Customized:Customized

- Standard:MISUMI

- Certification:TS16949, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Model NO.:S02-3-002

- Trademark:RootChina

- Origin:Qingdao Shandong

- HS Code:8480790090

- Production Capacity:100 Sets,Year

Description

Basic Info.

Model NO. S02-3-002 Runner Hot Runner Design Software UG Installation Fixed Certification TS16949, ISO Standard MISUMI Customized Customized Hot Runner Yudo Core Steel 2344 Lead Time 25-35 Days Injection Machine Size 50-1000 Tons Cold Runner Available Transport Package Wooden Box Specification CE/RoSH Trademark RootChina Origin Qingdao Shandong HS Code 8480790090 Production Capacity 100 Sets/YearProduct Description

RootChina established as a professional tools & dies manufacturer in China, provide one-stop solutions for plastics including mould manufacturer, injection molding, assembling and secondary processing services (printing/painting/plating).

Our Service:

1. DFM is provided before mold design.

2. CAE analysis is available if requested, such as Mold flow.

3. Steel certification and heat treat report is provided.

4. Weekly mold progress report with photos available.

5. Mold testing video/2D&3D drawings is provided before shipment.

6. Full dimension inspection report is available.

7. Warranty time: one year.

Our Advantage:

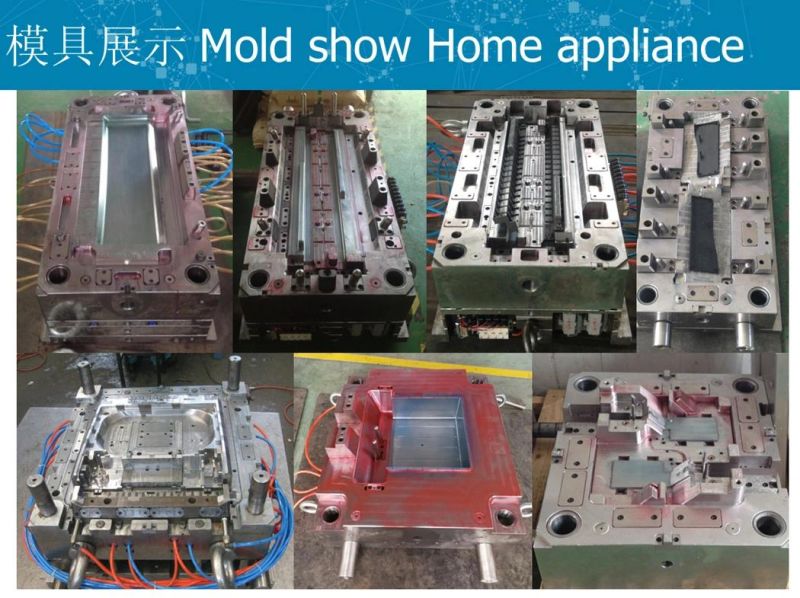

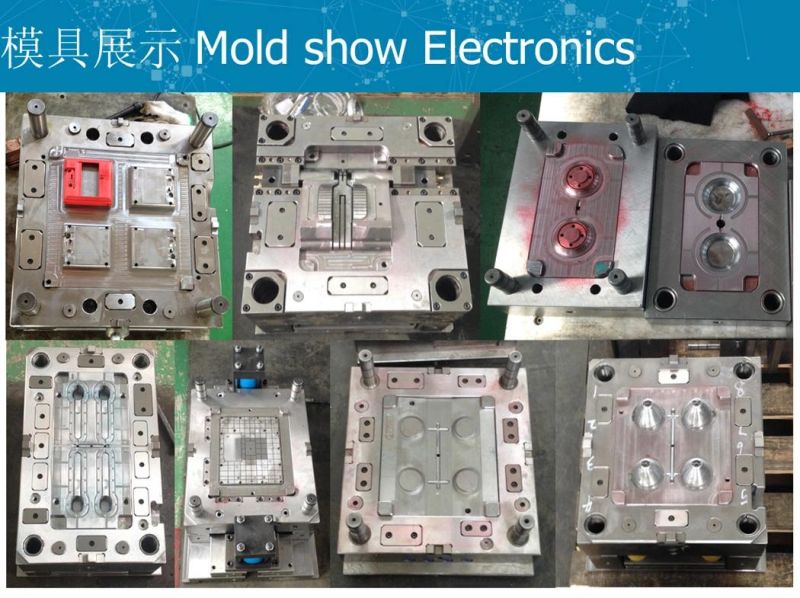

1. With more than 10 year experience in exported mould, especially for automotive moulds & household moulds, certificated by ISO9001:2008

2. Professional marketing engineer & project engineer promoted from mould designer with rich technical knowledge.

3. 2-3days fast response for inquiry, simple or urgent inquiry can be replied in one day.

4. Export about 100sets moulds to USA & Europe every year.

5. In house strict quality control.

6. Fast and on time delivery.

7. All moulds can work automatically.

What do we need for an mould inquiry?

1. Part drawings including 2D&3D

2D drawing indicates plastic material/tolerance/ finish request and so on.

2D drawing format: DWG or DXF file.

3D drawing format: STP/ X_T/ IGES /Solidwork/Proe/UG/CATIA and so on

2. Mould Cavity No:

Mould cavity No. affect price greatly. It depends on how many pcs parts do you want to produce one cycle time, also affect moulded parts price much.

3. Mould Life:

It depends on the volume you need the mould to produce. If the volume is big, recommend to use multiple cavities mould with high quality steel.

4. Cycle Time:

If the volume is big, cycle time affect part price greatly. We can build shorter cycle time tooling and create more value for you.

Facilities List

| No | Equipment Name | Brand | Origial Place | Model No: | Working Stroke | Quatity |

| 1 | Wire Cutting | Sodick | Japan | AQ600L3 | 600X400 | 1 |

| 2 | Wire Cutting | Sodick | Japan | AQ360LXS | 360X250 | 1 |

| 3 | Wire Cutting | Fangzheng | China | / | 500X450 | 3 |

| 4 | EDM | Sodick | Japan | AM30LS | 320X250 | 1 |

| 5 | EDM | Jingda | Taiwan | D350 | 350X250 | 2 |

| 6 | EDM | Qunji | Taiwan | QJ-345 | 400X500 | 2 |

| 7 | Milling Machine | Xuzheng | Taiwan | / | 600X350 | 6 |

| 8 | CNC | Youhong | China | S1060 | 1000X600 | 3 |

| 9 | Polishing Machine | Zhunli | Taiwan | 618 | 350X200 | 4 |

| 10 | Polishing Machine | Yalida | Taiwan | / | 350X200 | 4 |

| 11 | Polishing Machine | Dejian | Taiwan | / | 300X500 | 1 |

| 12 | Cliper | Mitutoyo | Japan | / | 200mm | 6 |

| 13 | Micrometer | Mitutoyo | Japan | / | 200mm | 2 |

| 14 | Projector | Mitutoyo | Japan | / | 300mm | 1 |

The information has been udated by RootSino on 22-3-21