OEM Service Plastic PVC Valve Moulding

HUASHENG PIPELINE TECHNOLOGY CO., LTD.- Process Combination Type:Compound Die

- Plastic Material:PVC

- Mould Cavity:Multi Cavity

- Surface Finish Process:Vacuum Hardening

- Shaping Mode:Injection Mould

- Application:Water Supply and Industry

Base Info

- Specification:customized

- Transport Package:Carton

- Customized:Customized

- Standard:PUNCH

- Certification:TS16949, ISO

- Installation:Fixed

- Design Software:AutoCAD

- Runner:Hot Runner

- Model NO.:HS-8500006

- Trademark:customized

- Origin:Changzhou, China

- HS Code:8481804090

- Production Capacity:60, 000 Tons

Description

Basic Info.

Model NO. HS-8500006 Runner Hot Runner Design Software AutoCAD Installation Fixed Certification TS16949, ISO Standard PUNCH Customized Customized Transport Package Carton Specification customized Trademark customized Origin Changzhou, China HS Code 8481804090 Production Capacity 60, 000 TonsProduct Description

COMPANY PROFILE Huasheng Pipeline Technology Co.,Ltd has been in business since 1988 and operates two modern factories of 200,000 square meters, with 30 pipe extruding lines, 80 mechanical processing equipment, 200 injection machines, and 400 employees.

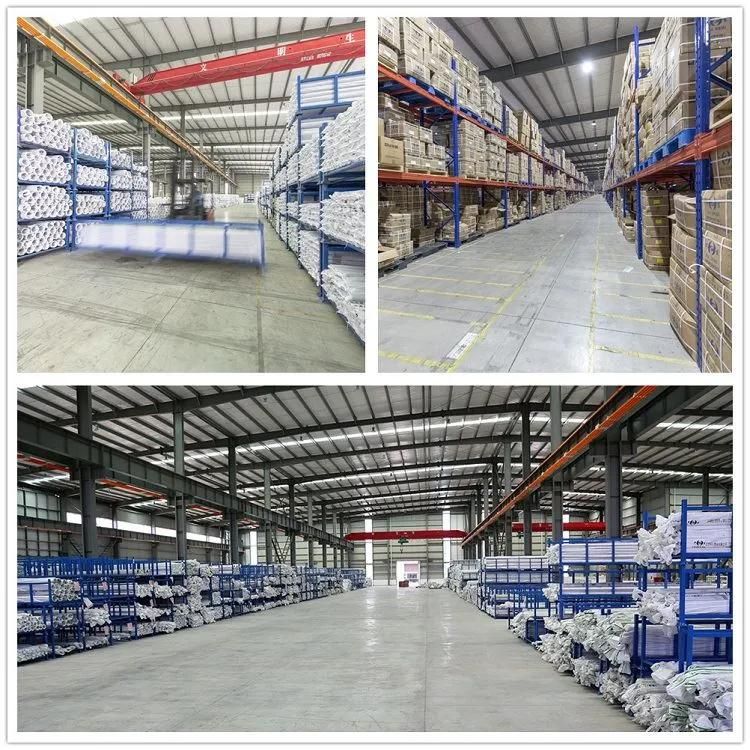

Huasheng Pipeline Technology Co.,Ltd has been in business since 1988 and operates two modern factories of 200,000 square meters, with 30 pipe extruding lines, 80 mechanical processing equipment, 200 injection machines, and 400 employees. The annual production has reached a sales turnover of USD 30,000,000, annual production capacity has exceeded over 80,000 tons, and storage is over 10,000,000 USD.

PVC Valves Mould

Description

| Mold material | M2316 |

| Origin | China |

| Product material | PVC |

| Shaping mode | Plastic injection |

| Mold base | Longji |

| Cavity | 1-16 |

| Surface finish process | vacuum hardening |

| Mould accuracy | 0.1-0.3mm |

| Designation time | 3-7days |

| Lead time | 20-45 days |

workshop exclusively for mold

1.Two WEDM-HS machines (Wire cut Electrical Discharge Machining ) for process mould request of complex size or small precision parts,such as punch die,fixed panels,a variety of micro-hole slot,narrow,arbitrary curves and so on.

2.CAMPRO from Taiwan has FANUC system.

3.Haas from USA for pattern making machine,totally 3 pieces differ from the Machine Tool's Movement.Graphite machine is used for lower the line.Usually partingline changes because of the product designation.In order to less lose of material and schedule for product development,we can use graphite to reprocess.

4.Two WEDM-LS machines from Mitsubishi (Wire cut Electrical Discharge Machining ) LS-WEDM plays an important role in the field of high-precision mould manufacture, shaped tool machining, hard-machined material and the machine of precise complex part.

5.Electric cutting machine from Japan,Taiwan,Korean and domestic market,Use the power of discharging to cut down the extra parts as the mould designation request.

6.Moriseiki from Japan,higher mechanical accuracy.