Custom Injection Plastic Housing Professional Plastic Injection Mould Manufacturer Plastic ...

Ningbo Moldor Plastic Co., Ltd.- Mould Cavity:Single or Multi Cavity

- Surface Finish Process:Polishing, Texture, Stand Blasting

- Warranty:Wearing Part - 1 Years for Free

- Shaping Mode:Injection Mould

- Plastic Material:PP, ABS, PC, PE, Nylon and So on

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Part Material:ABS,PP,POM,PA6,PE,PMMA and etc.

- Mold Material:Nak80, H13, S136, 718h, P20, S50c and etc

- Mould Life:0.5-1 Million

- Injection Moulding Machine:50t-1000t

- Customized:Customized

- Standard:Hasco or as Customers′ Request

- Certification:ISO

- Installation:Fixed

- Design Software:RO,E, Ug, Catia, Solidwork, Moldflow, Autocad

- Runner:Hot Runner or Cold Runnerot Runner or Cold Runner

- Model NO.:MD 100065

- Transport Package:Wooden Box

- Trademark:Custom Logo

- Origin:China

- HS Code:8480719090

- Production Capacity:350 Sets,Year

Description

Product Details

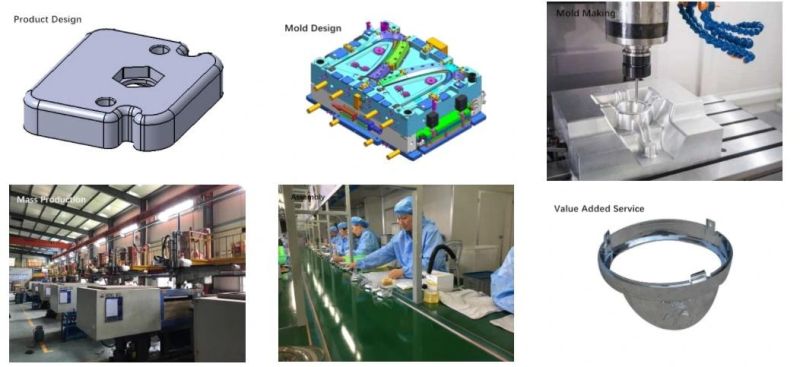

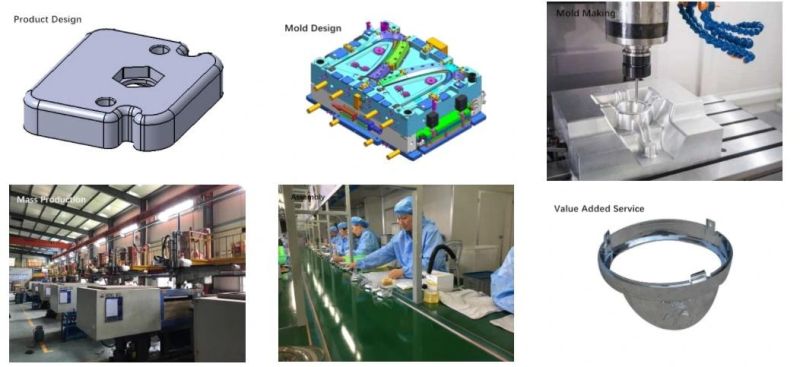

Factory Capability

Our tooling work is able to make different size of molds with single cavity or multi cavities. With your product data, our engineer can provide you the feasible project with low price and high quality. Below shows our manufacturing apability:

1. Maximum mold size 2500mm*2000mm*1500mm

2. Maximum mold weight: 15 ton

3. The highest machining precision: Our Service

Packaging & Shipping

FAQ

Q1:Are you a trading company or factory?

A1:We are factory.

Q2:What type of information is required for quoting a molding project?

A2:Please send your drawings or sample to us.

Q3:How long do you take to build a mold?

A3:The production timeline depends on your specific needs, normally the lead time is 25-45days.

Q4:How small or large of a plastic part will you produce?

A4:Our machine capabilities cover a range from 60-ton to 500-ton clamping forces.

Q5:What kind of steel do you use for plastic moldings?

A5:We can use any type of steel appointed by customer or popular in the market.Such as P20,718,8407,NAK80,H13,S136,

DIN 1.2738,DIN 1.2344,etc.

Q6:What types of materials can be molded by your injection products?

A6:Polystyrene,ABS,PET,TPR,TPU,PVC,Nylon,Acetal,Polypropylene,Polyethylene, Polycarbonates and etc.

Q7:Do you offer secondary service such as assembly, packaging or painting?

A7:Yes,such as assembly, painting, tapping, ultrasonic welding, trimming, sorting, customized packaging and etc.

Q8:If I have an existing tooling, could you use it to mold my project?

A8:Most certainly, if existing tooling is available, we can use them.

Q9:Can you mold around inserts or metal components?

A9:We can do insert molding with just about any metal and non-metal components.

Packaging & Shipping

Q1:Are you a trading company or factory?

A1:We are factory.

Q2:What type of information is required for quoting a molding project?

A2:Please send your drawings or sample to us.

Q3:How long do you take to build a mold?

A3:The production timeline depends on your specific needs, normally the lead time is 25-45days.

Q4:How small or large of a plastic part will you produce?

A4:Our machine capabilities cover a range from 60-ton to 500-ton clamping forces.

Q5:What kind of steel do you use for plastic moldings?

A5:We can use any type of steel appointed by customer or popular in the market.Such as P20,718,8407,NAK80,H13,S136,

Q6:What types of materials can be molded by your injection products?

A6:Polystyrene,ABS,PET,TPR,TPU,PVC,Nylon,Acetal,Polypropylene,Polyethylene, Polycarbonates and etc.

Q7:Do you offer secondary service such as assembly, packaging or painting?

A7:Yes,such as assembly, painting, tapping, ultrasonic welding, trimming, sorting, customized packaging and etc.

Q8:If I have an existing tooling, could you use it to mold my project?

A8:Most certainly, if existing tooling is available, we can use them.

Q9:Can you mold around inserts or metal components?

A9:We can do insert molding with just about any metal and non-metal components.