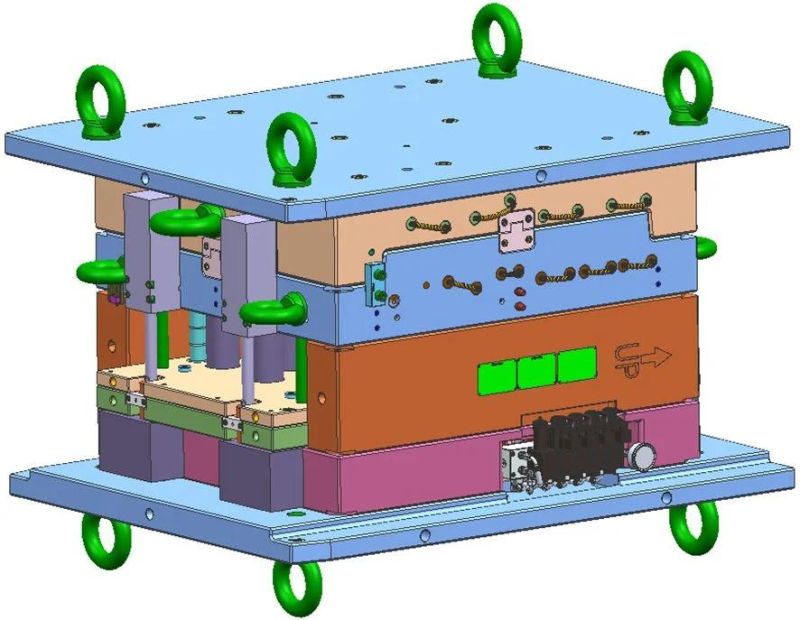

Automotive Low-Pressure Injection Molding Mould a Pillar Mould

Zhejiang JMT Technology Co., Ltd.- Plastic Material:PP

- Mould Cavity:Multi Cavity

- Surface Finish Process:Non Woven Fabric

- Shaping Mode:Injection Mould

- Warranty:1year

- Process Combination Type:Single-Process Mode

Base Info

- Transport Package:Wooden Box

- After-sales Service:1year

- Customized:Customized

- Standard:HASCO

- Certification:TS16949, ISO

- Installation:Fixed

- Design Software:UG

- Runner:Hot Runner

- Application:Car

- Specification:718H, 2738H

- Origin:China

- HS Code:8480710090

Description

1. What is low pressure injection molding

Low pressure injection molding process is a kind of packaging process that uses very low injection pressure to inject hot-melt materials into the mold and quickly solidify. With the excellent sealing performance and excellent physical and chemical properties of hot-melt materials, it can achieve the effects of insulation, temperature resistance, impact resistance, vibration reduction, moisture resistance, waterproof, dust-proof, chemical corrosion resistance, etc., and play a good role in protecting electronic components.

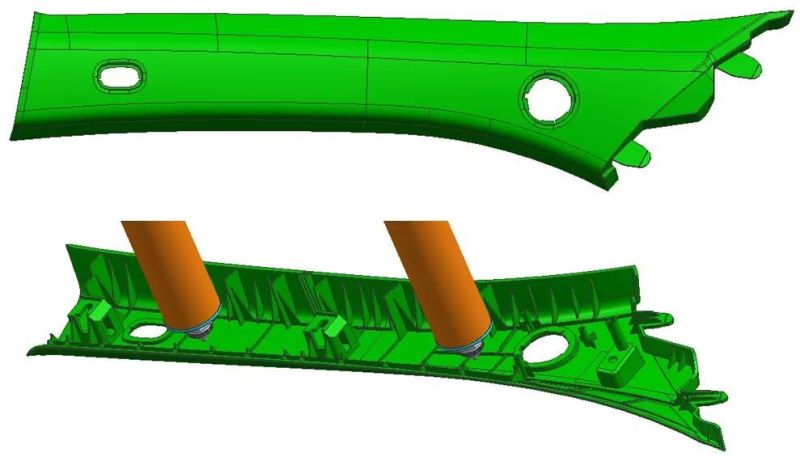

In the automotive industry, some automotive interior molding and electronic components packaging will use this process.

2. Molding process and Application

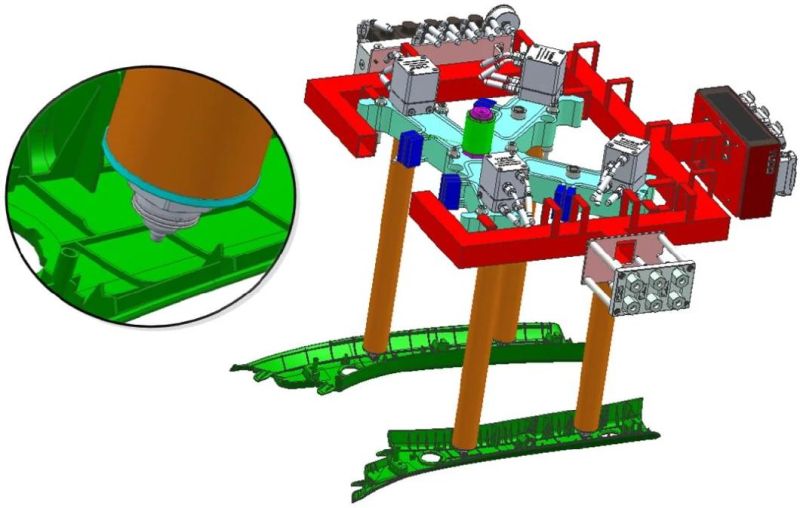

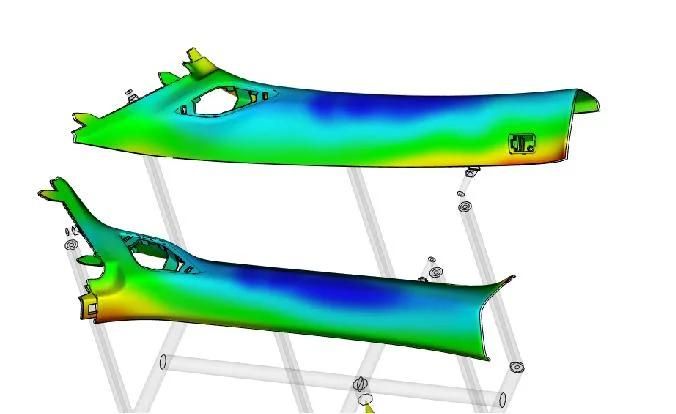

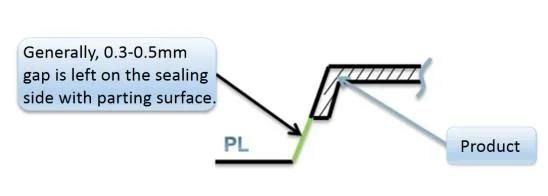

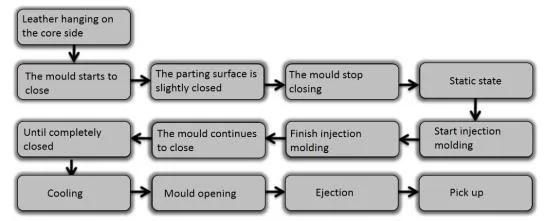

The skin is put into the mold in advance, and then the plasticized plastic in the molten state is injected into the closed mold cavity with the help of the push force of the screw, and the product is obtained after curing. The materials used for low pressure injection molding skin can be cloth, leather, PVC fabric, TPO with PP foam and PUR skin. At present, the technology has been widely used in the production of automobile door guard, pillar guard and parcel shelf guard. Many high-end interior parts adopt low-pressure injection molding process, such as Mercedes Benz, BMW door panel inlay, etc

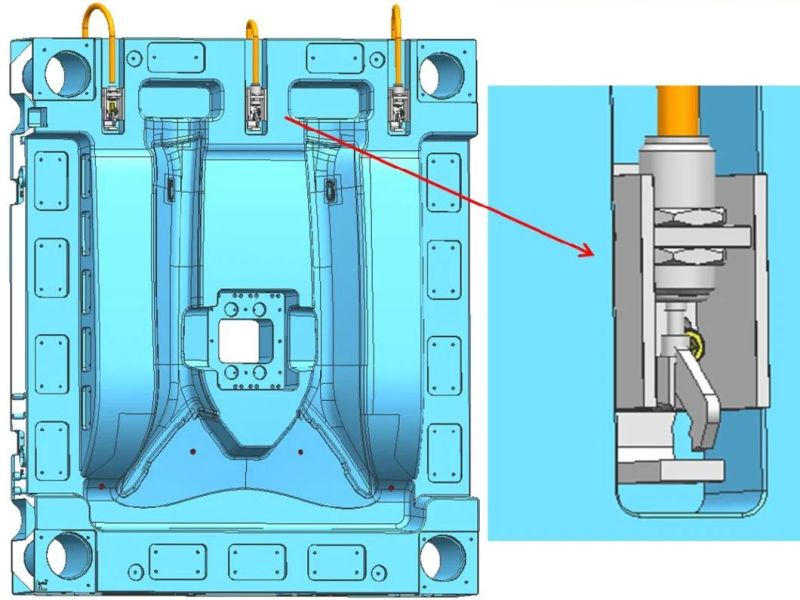

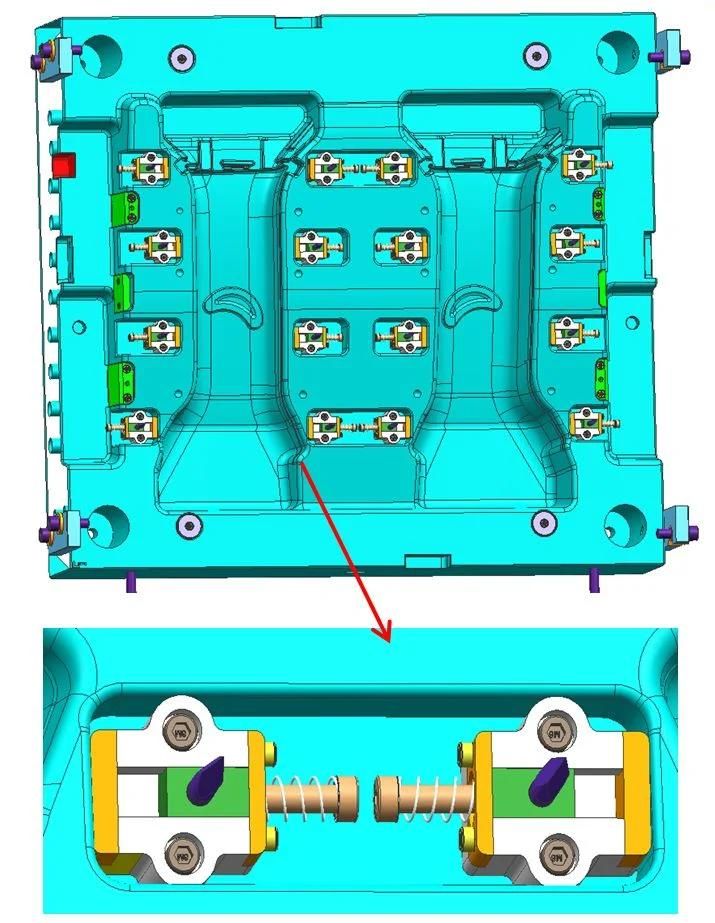

4. Several ways of hanging cloth for low pressure injection mold

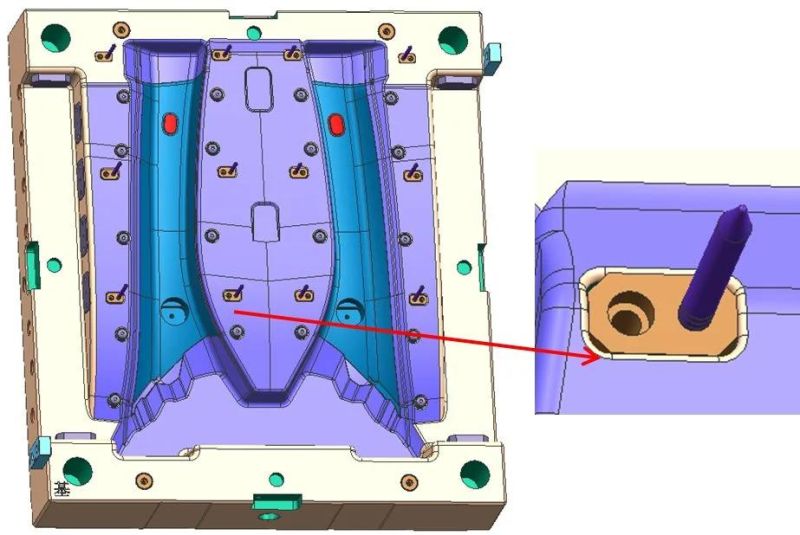

The first type: fixed hanging needle

The hanging needle is not adjustable, which is suitable for flat products. It can save the mold space by using the extensibility of the fabric itself, but it is easy to tear the fabric. When the mold has two cavities, it needs to hang cloth separately.

Second: adjustable hanging needle

Second: adjustable hanging needleIt is suitable for products with large drop and complex shape. The hanging needle can be adjusted by itself, which can effectively protect the fabric.

The third: the use of hook form

The hook form is used to clamp the fabric and make the fabric hang vertically. This form is easy to operate and avoid the sharp part of the hanging needle sticking to people. The fabric can be adjusted automatically in the mold closing process and is not easy to wrinkle.