Plastic Car Accessories Engine Intake Snorkel Kits Plastic Mould/Motorbike Parts, Free ...

Sum Shun Plastic Moulding (ShenZhen) Co., Ltd.- Process Combination Type:Single-Process Mode

- Plastic Material:ABS

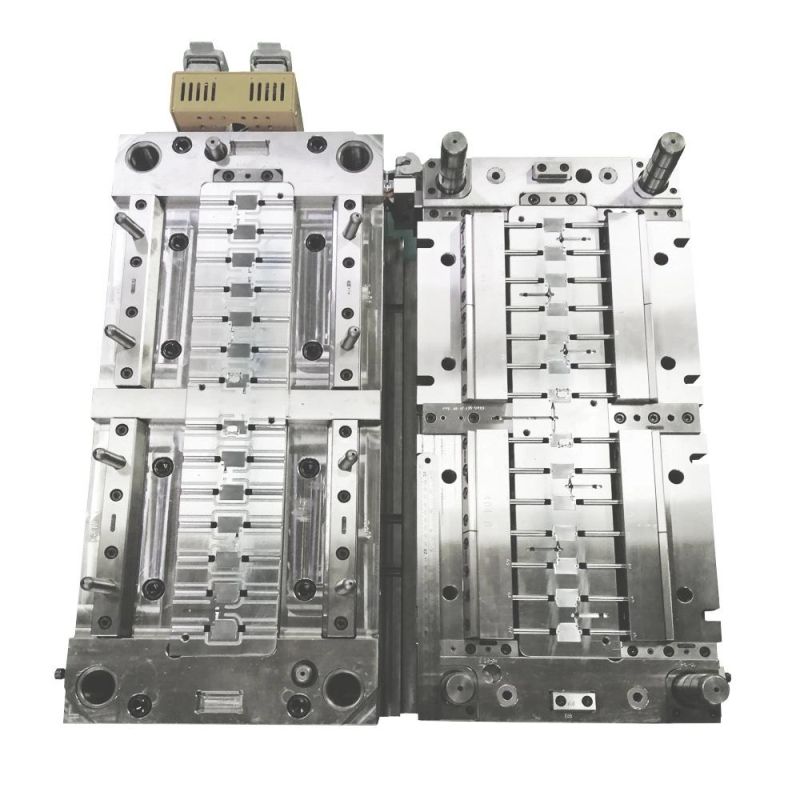

- Mould Cavity:Multi Cavity

- Shaping Mode:Injection Mould

- Surface Finish Process:Sand Blasting

- Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Base Info

- Cavity Number:2 + 2

- Mould Base:Lkm

- Injection Machine:700 T

- Core & Cavity Steel:S136

- Gate Point:Pin Point Gate

- Net Weight:2805 Kg

- Customized:Customized

- Standard:HASCO

- Certification:ISO

- Installation:Fixed

- Design Software:UG

- Runner:Cold Runner

- Model NO.:D40 LLDPE

- Transport Package:Wooden Box

- Specification:900mm X 1250mm X 700mm

- Origin:China

- Production Capacity:50 Sets,Month

Description

Basic Info.

Model NO. D40 LLDPE Runner Cold Runner Design Software UG Installation Fixed Certification ISO Standard HASCO Customized Customized Net Weight 2805 Kg Gate Point Pin Point Gate Core & Cavity Steel S136 Injection Machine 700 T Mould Base Lkm Cavity Number 2 + 2 Transport Package Wooden Box Specification 900mm X 1250mm X 700mm Origin China Production Capacity 50 Sets/MonthProduct Description

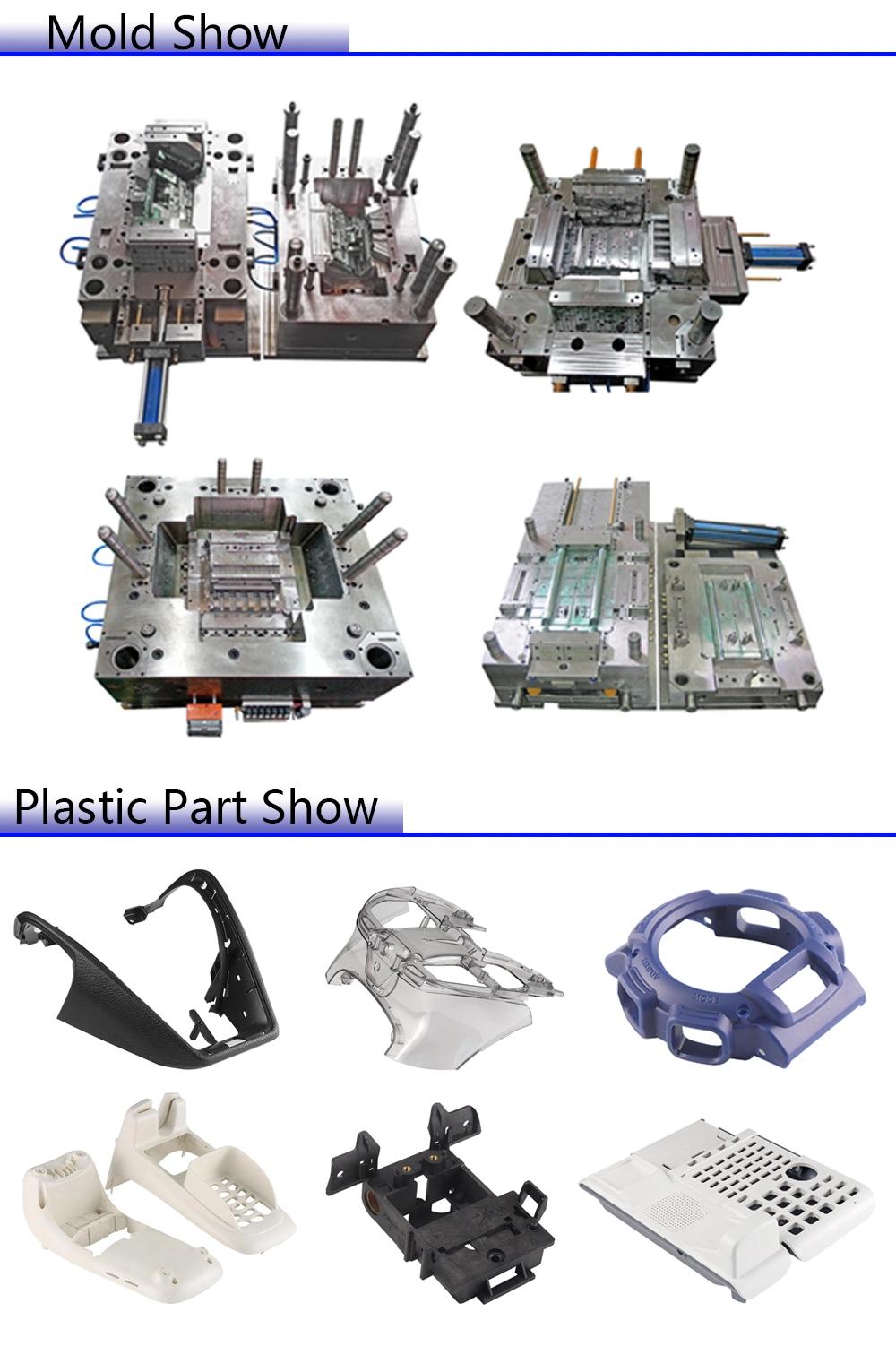

Sum Shun Plastic Moulding Co., Ltd is a professional plastic injection mold manufacturer, who has engaged in all kinds of injection mold making for over 20 years. 20 not only is a number but also means learning, growth and experience to us. We are always keeping our best attitude to turn your idea and design into a perfect reality with our expertise, and to make our service better and better. Whenever you need, we are here and seeking any opportunity to cooperate with you. Welcome to contact!Free Technical Consulting Available!

| Project Item | Injection Plastic mold |

| Mould making service | OEM/ODM |

| Design software | Pro/E, UG, Solidwork, Moldflow, AutoCad, etc. |

| Parts material | ABS, PC, PP, PBT, BMC, PMMA, PC+ABS, PP+TD20%, PU, PE, PVC..Etc |

| Cavity number | Single or Multi |

| Gate point | Edge gate, Slid gate,Sub gate,Direct gate, Pin point gate, Valve gate, etc. |

| Runner | Hot or Cold |

| Core & Cavity steel | NAK80, S136, SKD61, P20,1730hh, 2738hh, 718h, H13, BPMHH, 2343hh, etc. |

| Mold base steel | 45, S55C, P20, 1730, 2738, 718h, H13, BPMHH, 2343ESR |

| Mould base | LKM, DME, HASCO, ETC. |

| Injection machine | 90T-1500T |

| Cycle time | 10-120 seconds |

| Mould Life | 300,000 - 1,000,000 shots |

| Quality assurance | ISO 9001:2015,ISO 14001:2015 |

| Tooling lead time | 20-40 days |

| Shipping Packing | Wooden case or according to customer's requirement |

Q. I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A. Yes! We are happy to work with potential customers to evaluate the technical feasibility of your ideas or design and we can advise on materials, tooling and set up the costs to you for reference.

Q. My components have been developed on CAD. Can you use the drawings?

A. Yes! We accept DWG, DXF, IGES, Solidworks and Rhino format's files, and will base on your drawings to quote and build up 3D products and mould toolings.

Q. Can I test my idea/component before committing to mould tool manufacture?

A. Yes! We are providing prototype service, can use CAD drawings to make models for functional evaluations and design improvement.

Q. Can you make the mold and also supply us the injection molding plastic product?

A. Yes! We provide molding, producing, painting, assembly and packaging service.